Fabric stretch and recovery are critical properties in the textile industry, especially for garments where fit, comfort, and durability are key. The ability of a fabric to stretch and return to its original shape impacts how it performs under various conditions.

Testing Instruments and Standards

This study leverages the Stretch and Recovery Testing Instrument—a precision tool designed to measure the elongation and recovery of fabrics under controlled conditions. The following standards form the benchmarks for assessing fabric performance:

- ASTM D3107: Applicable to woven fabrics, this standard measures stretch properties under specific loads.

- ASTM D2594: Used for knitted fabrics, this standard evaluates stretch and recovery behaviour, ensuring fabrics meet quality requirements.

These standards ensure consistency and reliability across different studies, providing robust data for comparative analysis.

Woven Fabrics (ASTM D3107)

Testing Procedure:

Stretch the fabric for 10 seconds.

Measure fabric growth after 15 seconds and 30 minutes at 85 per cent extension.

Requirements:

Fabric Growth: Maximum 3 per cent after 15 seconds and 30 minutes.

Recovery: Minimum 75 per cent after 15 seconds and 85 per cent after 30 minutes.

Testing reveals that woven fabrics exhibit controlled stretch and strong recovery properties, making them ideal for structured garments like trousers and blazers. The tighter weave construction plays a significant role in maintaining shape and minimising deformation under repeated stress.

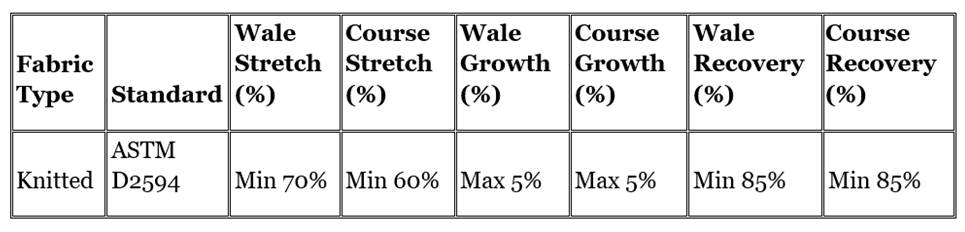

Knitted Stretch Properties

Knitted fabrics, with their inherently elastic structure, offer greater stretch but pose challenges in recovery. Using ASTM D2594, the study evaluates:

- Variations in performance due to differences in fibre content and construction.

- Recovery behaviour under specific loading conditions, such as 4 lbs weight tests.

Observations highlight the importance of addressing potential issues such as fabric growth and bubbling in high-stretch zones. For example, areas like knees and elbows are prone to distortion, which must be mitigated through technical adjustments.

Knitted Fabrics (ASTM D2594)

Knitted fabrics were tested under cyclic loading, with a 4 lbs weight applied to assess elongation and recovery. Results showed higher elongation compared to woven fabrics, but recovery performance varied depending on fibre composition and construction.

Strategies for Maintaining Good Stretch and Recovery

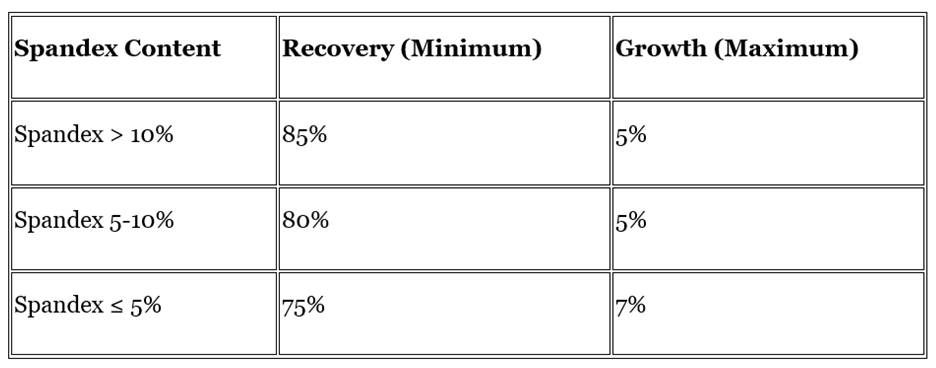

Achieving optimal stretch and recovery requires attention to several factors:

- Fibre Composition:

• Incorporating elastomeric fibres like spandex or Lycra enhances stretch and recovery.

• Blending with stable fibres such as cotton or polyester ensures durability.

- Fabric Construction:

• Tight weaves in woven fabrics and well-engineered knit patterns improve recovery.

• Adjusting yarn tension during production can prevent excessive growth.

- Finishing Processes:

• Heat setting stabilises stretch fabrics, locking in desired properties.

• Chemical finishes, such as durable press treatments, enhance recovery without affecting hand feel.

- Testing and Quality Control:

• Regular testing under simulated real-world conditions ensures fabrics meet recovery standards.

• Cyclic loading tests mimic repeated wear.

- Design Considerations:

• Reinforcing high-stress areas with additional stitching prevents excessive stretching or bubbling.

• Garment patterns should accommodate fabric behaviour to maintain fit and aesthetics.

Comparative Study Results

Key Findings:

- Woven Fabrics:

- Superior in maintaining shape due to tighter construction.

- High recovery rates make them suitable for structured garments.

- Knitted Fabrics:

- Offer greater comfort and flexibility but require advanced techniques to manage growth and recovery.

- Ideal for performance wear where elasticity is prioritised.

A 4 lbs loading comparison study under ASTM D2594 reveals that woven fabrics maintain controlled stretch, whereas knitted fabrics exhibit higher elongation but may struggle with recovery in some cases.

Conclusion

Adhering to stretch and recovery standards play a critical role in ensuring that fabrics meet consumer expectations for durability, fit, and comfort. By optimising fibre composition, fabric construction, and finishing processes, manufacturers can produce high-performing fabrics that balance stretch and recovery effectively. Future advancements should focus on innovative materials and techniques to address persistent challenges, enhancing both functionality and style.