Why do isopropyl alcohol purity levels matter for microchips?

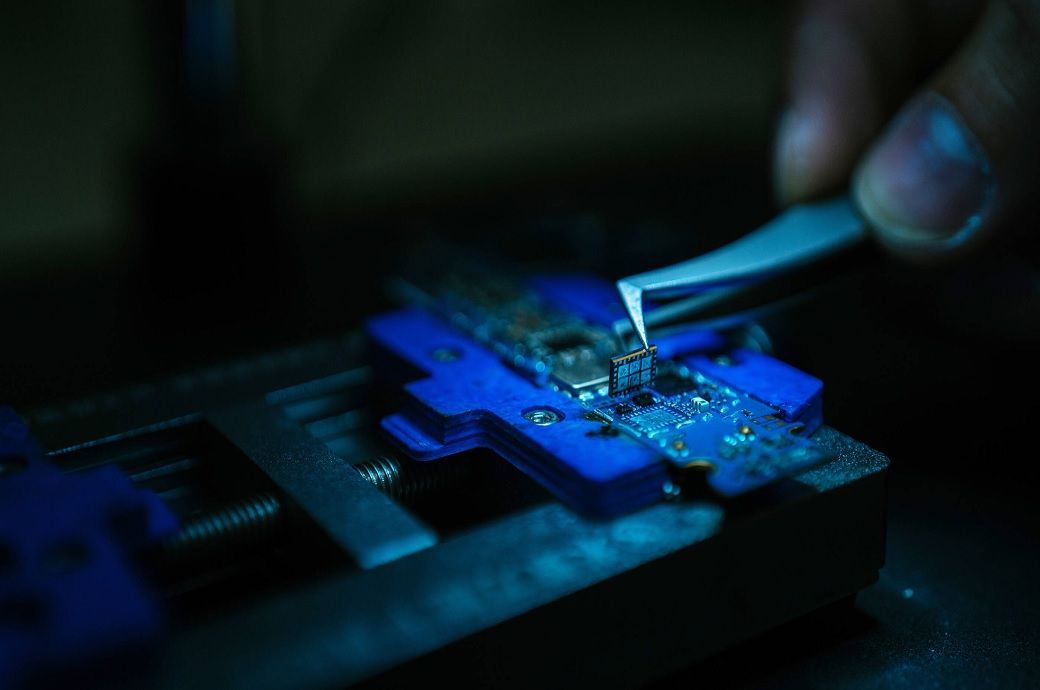

While 99.9% purity IPA is great for hand sanitizers and household cleaning solutions, next generation semiconductors need 99.999% pure IPA to avoid damaging delicate microchips. As chips evolve into smaller devices—sometimes as small as 2 nanometers, meaning 150,000 chips can fit across a grain of salt—higher IPA purity becomes essential. These chip nodes, or information hubs compressed into small devices, require ultra-pure IPA for drying wafer surfaces, reducing impurities and preventing damage. Advanced chip makers rely on this high-purity IPA to minimize defects in their sensitive circuitry.

What’s our history in supplying the isopropyl alcohol market?

From household cleaning to high tech, we’ve evolved IPA production in many ways over the past century. We started commercial production of IPA in 1920 and we have been serving semiconductor applications since 1992. During the COVID-19 pandemic in 2020, we were the largest producer of IPA in the United States for hand sanitizers.

How will we support U.S. chip manufacturing with high-purity isopropyl alcohol?

Producing 99.999% purity IPA is our next step to evolve with this market. The semiconductor chip manufacturing industry needs a reliable domestic supply of ultra-pure IPA, and we are committed to providing it. We’re doing that by upgrading our Baton Rouge plant, the world’s largest plant for isopropyl alcohol1, to meet this growing demand by 2027. Our experience and expertise at our Baton Rouge manufacturing complex uniquely position us to provide an end-to-end American supply chain for IPA to U.S.-based chip manufacturers.

ALCHEMPro News Desk (RM)

Receive daily prices and market insights straight to your inbox. Subscribe to AlchemPro Weekly!