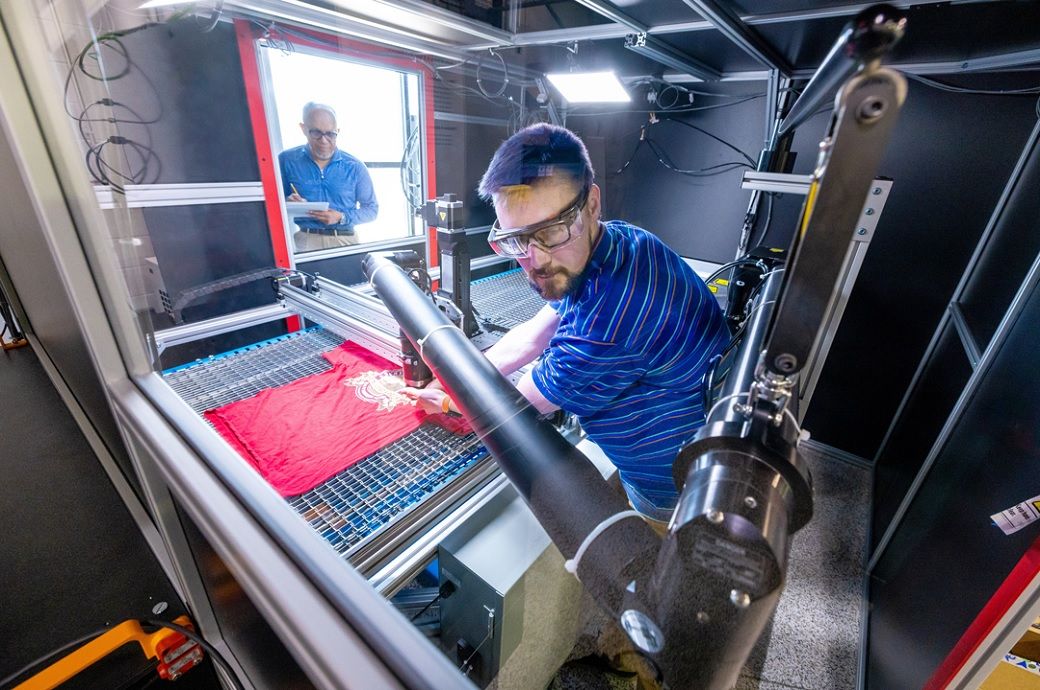

Led by programme manager Mark Walluk, the team, consisting of staff engineers Ryan Parsons ’17 (mechanical engineering), Nick Spears ’24 (robotics and manufacturing engineering technology), Sri Priya Das, Ronald Holding and Christopher Piggot ’91 (computer engineering and technology), as well as associate research professor Abu Islam, is using an automated system to detect and remove these non-recyclable elements to enable higher-value material recovery.

The process begins with a conveyor-fed imaging station where three specialised cameras generate a high-resolution, multi-dimensional map of the garment which allows for fibre composition analysis down to the millimetre level.

The system then leverages artificial intelligence and machine vision to identify and remove non-recyclable elements from clothing, which proved to be a unique challenge for the team.

“In traditional manufacturing, these automations have been used for decades and it’s predictable,” said Islam, who collaborated with Das on the AI integration. “You know what part is coming next and exactly where it goes. In used clothing, every item is different. That unpredictability means the system must make on-the-spot decisions.”

To meet that challenge, Islam and Das developed vision-guided algorithms that identify features like logos, collars, and cuffs, and interpret infrared reflections for definition of fibre type. That data is then passed to a robotic laser-cutting system that cuts those features with precision and speed, without damaging reusable material. Once cut, the garment advances to a robotic sorting gantry, which places the clean material into separate bins for recycling. The prototype can process a new garment roughly every 10 seconds, as per the study.

Walluk noted that the system was built with scalability and real-world complexity in mind, so it is both economical and ready to replicate.

“It’s not going to solve the world’s textile waste problem, but it’s a step toward a more circular economy,” Walluk said. “Today, recyclers prefer post-industrial fabrics because of their predictable material properties. We’re working to advance beyond that step by transforming post-consumer clothing into high-quality, reliable feedstock also. This makes these materials not only viable, but preferable, helping divert them from landfills.”

Key collaborators include Ambercycle, a Los Angeles-based company pioneering polyester recycling, and Goodwill of the Finger Lakes, which provided garments for testing and insights into the resale and reuse market. Nike contributed industry guidance in the project’s early stages.

The work, which began in 2023, was funded through a grant of nearly $1.3 million from the REMADE Institute, a public-private partnership focused on developing circular manufacturing solutions. The team presented its work at a global REMADE conference this past April in Washington.

“Textile recycling is a critical global challenge, and we’re proud to collaborate with industry leaders to drive meaningful solutions,” said Nabil Nasr, director of GIS and CEO of the REMADE Institute. “This effort not only creates significant environmental impact but also represents a major area of growth and innovation for us at GIS.”

Though still in the pilot phase, the technology is already attracting interest globally from recyclers in the US, Europe, South Asia, and Latin America. The team anticipates transitioning the system to its partners for continued testing and potential deployment later this year.

ALCHEMPro News Desk (RR)

Receive daily prices and market insights straight to your inbox. Subscribe to AlchemPro Weekly!