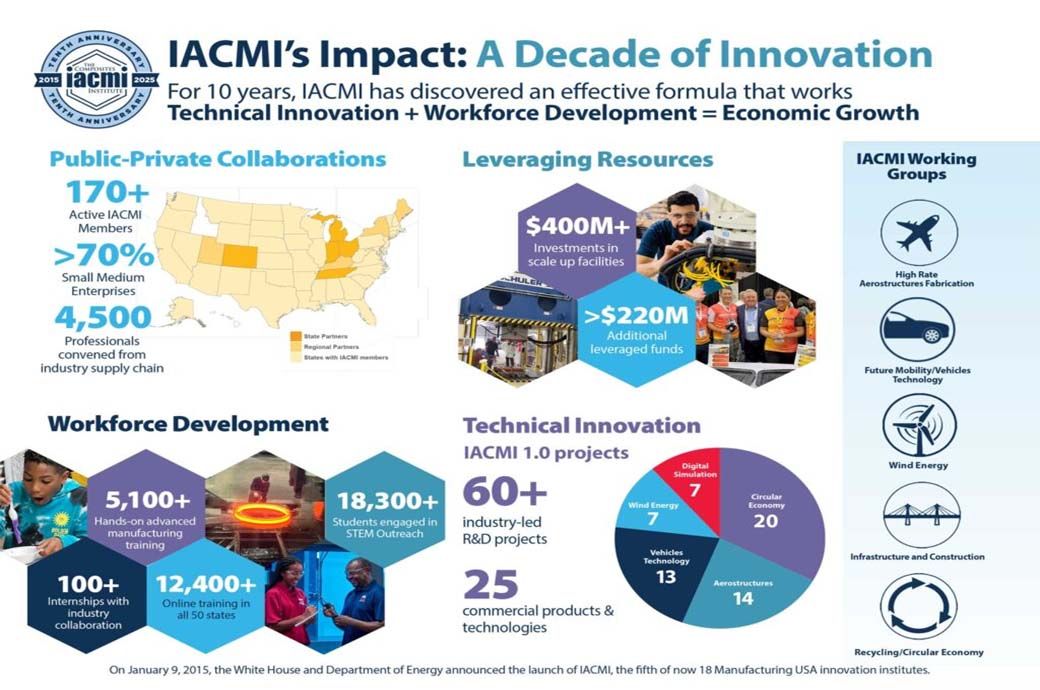

For 10 years, IACMI has played a pivotal role in America's reindustrialisation, aiming to secure its position as a global leader in manufacturing innovation and workforce development. Reshoring initiatives have been the key to bolstering US economic and national security. Through multiple national workforce programs sponsored by DOE and the department of defense (DoD), IACMI has been inspiring, educating, and training a skilled workforce to help address the projected 4.6 million open manufacturing jobs in the coming decade.

"For 10 years, IACMI has harnessed the power of public-private partnerships to improve products, processes, and people's lives through composite innovation and workforce solutions that secure America as a global leader in advanced manufacturing," said Chad Duty, chief executive officer for IACMI. "With steadfast investment and support from industry and government partners, notably DOE and DoD, IACMI has empowered domestic manufacturers to accelerate design and commercialisation, fostering a more reliable, secure, and competitive US economy."

Since 2015, IACMI, the DOE, and state economic development organisations have invested in a shared infrastructure that collectively delivers a breadth and scale of open-access advanced composites manufacturing R&D capabilities that stand unmatched in the US. These facility and infrastructure investments have been led by IACMI's core innovation partners in Colorado, Indiana, Michigan, Ohio, and Tennessee. These capabilities uniquely position IACMI to build on past achievements, de-risk future research, and accelerate onshoring efforts in the United States.

IACMI has leveraged these facilities to undertake transformational R&D, in nation-critical industries including energy, transportation, aerospace, and infrastructure & construction. An IACMI-sponsored project team helped Volkswagen of America redesign and validate a composite liftgate for SUVs, reducing the weight by 35 per cent and lowering its recurring cost by 9 per cent compared with steel. Technological advances from this research are now being used across multiple VW platforms, including the new VW ID Buzz EV. The scaling, manufacture and testing of novel thermoplastic wind turbine blades that are recyclable and lower in cost has also been demonstrated. Further research in automating finishing processes for wind blades aims to reshore wind manufacturing jobs. Simulation and modeling work to develop a virtual twin for additive manufacturing is revolutionising the production of tooling, IACMI said in a press release.

As the first DOE institute to receive renewed funding in 2023, and with DoD investments expanding proven programmes, IACMI is committed to building on these successes. Over the next few years, IACMI and its partners will leverage their full-scale facilities and equipment and significantly expand programmes. In this next chapter, IACMI will advance its purpose to convene, connect, and catalyse the US composites community by attracting startups and small enterprises while creating opportunities with large enterprises, national labs, and universities.

ALCHEMPro News Desk (RR)

Receive daily prices and market insights straight to your inbox. Subscribe to AlchemPro Weekly!