Currently, in addition to foams, nonwovens are mostly used as sound absorbers. However, these are relatively thick and not very stretchy. Textile fabrics such as woven or knitted materials are more elastic and flexible and are able to reduce noise more specifically in certain frequency ranges. This allows them to be individually adapted to existing or expected noise problems. However, these textile fabrics have rarely been used in acoustics to date.

In order to exploit this potential, research and development are encountering a problem: the measurement methods and simulation models used for nonwovens are not readily applicable to other types of textiles. Nonwovens consist of loosely arranged, interconnected fibres; they have what is known as a random fibre arrangement. In woven and knitted fabrics, on the other hand, the fibre arrangement has a recurring, non-random pattern. The different fibre arrangements result in significant differences in material properties. Due to a lack of alternatives, manufacturers of acoustic textiles still have to use these limited methods for their product development, DITF said on its website.

This is where the MetAkusTex research project comes in. Dr Elena Shabalina, head of the technology centre e-textiles & acoustics at the DITF, explained, "In acoustics research, there is limited knowledge about the potential and diversity of textiles. As a textile research institute, we want to ensure that a wide range of textile structures, including 3D textiles, find their way into the world of acoustics. We are laying the necessary foundations for this."

The DITF are developing new acoustic measurement and prediction methods that can be used to evaluate how different textiles interact with sound, whether they absorb, reflect, or scatter it. With the help of mathematical models, textile materials can be tested, adapted, and optimised for their acoustic effect as early as the design phase.

The project results will help companies make their product development processes more efficient and to design materials in a more targeted manner, for example, to make them sustainable. This will shorten time to market.

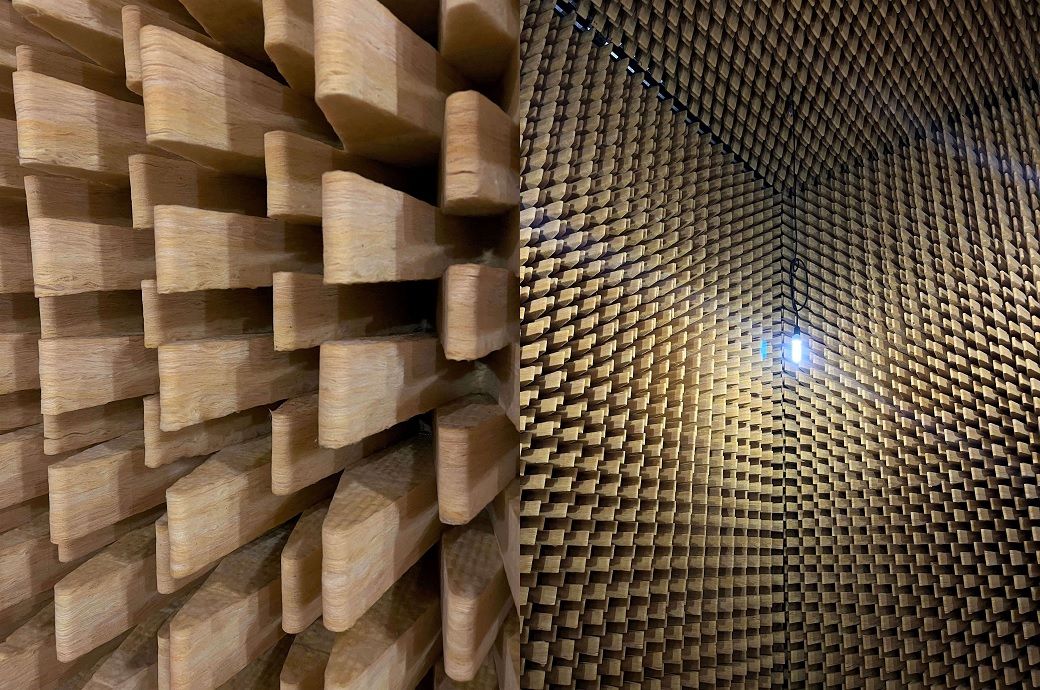

In addition to the development of new measurement methods, the acoustics laboratory at the DITF is being expanded. The measuring room with sound-absorbing walls and a sound-reflecting floor (semi-anechoic chamber) will be equipped with a modern data acquisition system. In addition to software, this includes various measuring microphones, loudspeakers, and a turntable to measure the sound quality of loudspeakers from different directions. The new acoustics laboratory will be used for research at the institute and will also be made available to industry for testing.

ALCHEMPro News Desk (RR)

Receive daily prices and market insights straight to your inbox. Subscribe to AlchemPro Weekly!