To achieve growth and success, manufacturers must prioritise the needs and preferences of their customers and focus on delivering value through their products and services. By understanding and meeting customer demands, manufacturers can build strong and lasting relationships, which will ultimately lead to sustainable growth and competitiveness in the market. The shift from a traditional production-focused mindset to a customer-oriented one is essential for manufacturers to adapt to changing market dynamics, stay relevant, and thrive in today’s business landscape, The Yarn Bazaar said in a press release.

“The manufacturing industry now has to think like the service industry. Unless and until they do not start to think like the service industry they can’t grow,” said Sanjay Arora, associate director, Wazir Advisors.

In the Indian textile industry, realising the value of an educated workforce can have a transformative impact. By providing comprehensive training to the workforce, companies can nurture a culture of quality at every level within the organisation. Well-trained employees are better equipped to handle challenges, adapt to technological advancements, and maintain consistent production standards. This, in turn, enhances productivity and efficiency, leading to improved customer satisfaction and brand reputation.

“Investing in employee training programmes is a game changer. Then only can you create a culture of quality at every level within the company,” said Balkrishna Sharma, joint president and business head, Ginni Filaments Ltd.

“Based on the segment we are operating in, we have to ensure that we have to have optimum quality at the best cost possible, utilising the resources, i.e., man, material, and machine,” said Vikas Sharan, former director, India operations, Saurer Textile Solution Pvt Ltd.

In the Indian textile industry, achieving optimal quality at the best possible cost is a paramount objective for sustainable growth. It necessitates a careful assessment of the segment in which a company operates to tailor strategies accordingly. By efficiently utilising resources, including skilled labour, quality materials, and advanced machinery, manufacturers can strike the right balance between cost-effectiveness and uncompromising quality.

For businesses in this sector, the ultimate measure of quality is the customer index, reflecting repeat orders and positive word-of-mouth referrals. When customers are delighted with the products and services, they not only return for more purchases but also become brand advocates, spreading positive reviews to attract new clientele.

“Quality for me is customer index, by which I get repeat orders and the same customer gives mouth publicity to give more and more orders. This is the quality parameter for me,” said Vilas Gharat, MD Gharat & Associates, on customer retention.

Achieving a high customer index requires an unwavering commitment to delivering superior products, meeting specific requirements, and addressing customer preferences. It involves understanding the ever-evolving needs of consumers and adapting swiftly to market trends.

Ensuring quality goes beyond just the end product; it encompasses every aspect of the supply chain, from sourcing raw materials to packaging and labelling.

Dr. Amit Lath, CEO of Sharda Group of Companies, shared a real-time case study where a small act of negligence costed the business a lot and impacted the profitability of the business. Such incidents emphasise the importance of vigilance and attention to detail at every level of the manufacturing process. Quality assurance measures should be integrated throughout the organisation, fostering a culture.

“Cultural change needs to come at various levels. Sometimes we receive the products with the right quality but there are other complications that we might see like wrong labelling or wrong cartons. Quality needs to be assured at every level,” said Dr Lath.

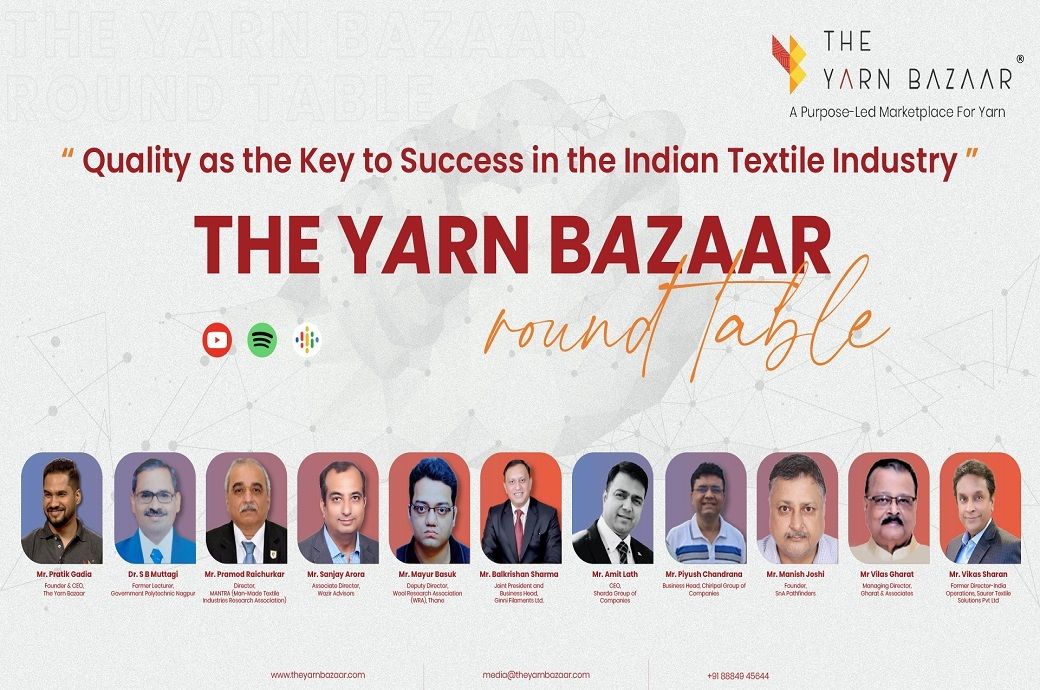

Other notable participants included Piyush Chandarana (business head of Chirpal Group of Companies), Manish Joshi (founder of SnA Pathfinders), Dr. SB Muttagi (former lecturer at Govt Polytechnic Nagpur), Pramod Raichurkar (director at MANTRA), and Mayur Basuk (deputy director at WRA), who shared their profound insights on the subject of quality.

ALCHEMPro News Desk (NB)

Receive daily prices and market insights straight to your inbox. Subscribe to AlchemPro Weekly!