The new process does not require additional equipment for pre- and post-treatment. By way of eliminating pre- and post-treatment, this has led to huge water and energy savings, and provides a competitive edge in the sustainable direct-to-fabric printing category, according to a press release by ColorJet.

ColorJet’s specialised pigment ink with binder offers a greener solution by way of the eliminating process in digital textile printing. Polymerisation at 160° after printing provides excellent colour fastness and print quality with a production capacity of 2500 linear metre/day.

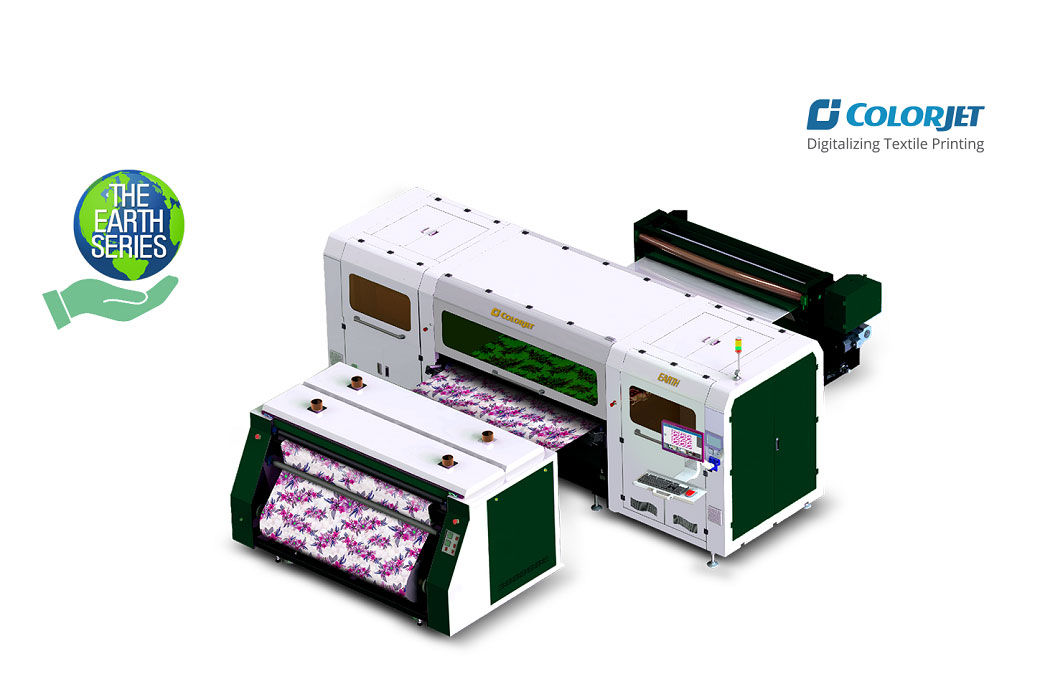

The Earth series comes with three models: 32, 16, and 8 inkjets powered by Konica Minolta print heads, with the combination of ColorJet’ s three new technologies—Kiloton, Purge Plus, and Osci Plus.

Purge Plus technology ensures removal of air bubbles from print heads and helps in saving almost 3-4 per cent of the total ink used in the printing process. Kiloton has increased the print head life to a considerable extent of up to three years.

Osci plus precise rollers for efficient tension control and smooth feeding of the fabric irrespective of any fabric help to accommodate almost every kind of fabric for direct printing. Inspired by the success of pigment solutions, Osci plus is operating successfully across the globe including India, Germany, Brazil, Vietnam, Pakistan, and at other leading textile clusters.

The Colorjet Earth Series will provide sustainable print solutions in textiles for fashion apparel, kidswear, home furnishings, and many other segments.

Visitors from the textile printing segment can view the live demonstration of the product at India ITME starting from December 8–13 at India Expo Centre and Mart, Hall No. 5, Booth No. H5F3G4.

ALCHEMPro News Desk (NB)

Receive daily prices and market insights straight to your inbox. Subscribe to AlchemPro Weekly!