Three of the PMI sub-components (new orders, output and suppliers' delivery times) were consistent with an improvement in overall operating conditions during March. Although the sub-indices tracking employment and stocks of purchases both signalled ongoing downturns, rates of contraction eased sharply since February.

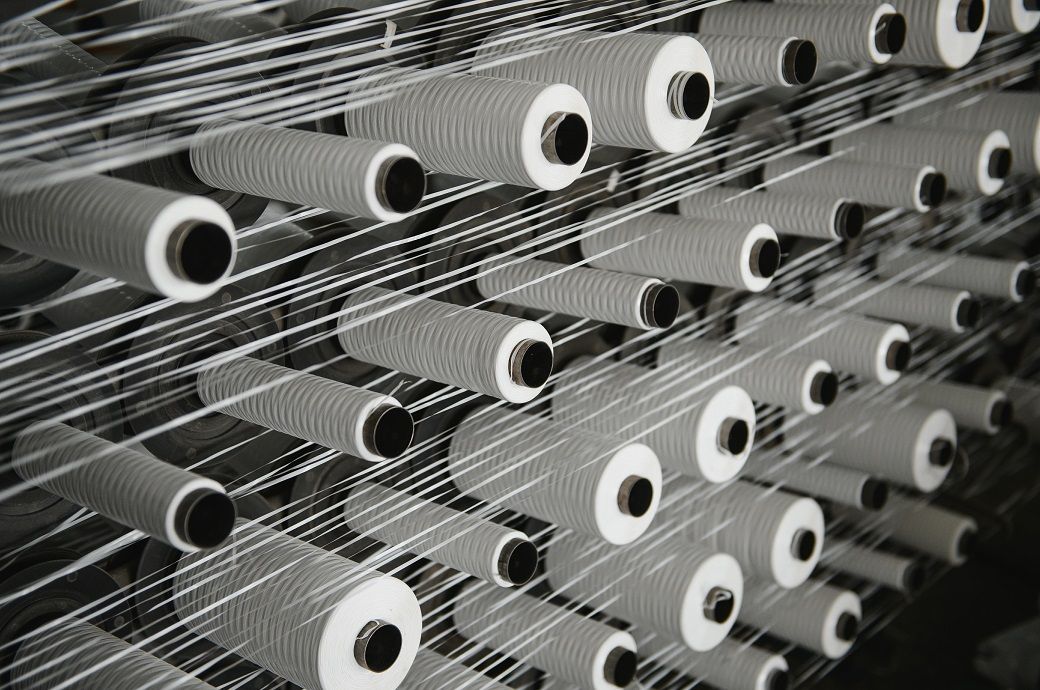

Manufacturing production increased for the first time since February 2023, as output growth in the consumer goods sector more than offset downturns in the intermediate and investment goods categories. Where an expansion of production volumes was registered, this was linked to client restocking supporting a rise in new order intakes, as per S&P Global.

March data signalled that the mild uptick in new business inflows was centred on the domestic market. The trend in new export orders remained weak in comparison, with overseas demand falling for the twenty-sixth successive month (albeit at the slowest pace since April 2023). Companies reported reduced demand from mainland Europe, with specific reference to France, the Netherlands, Belgium, and Poland.

The end of the opening quarter saw business optimism rise to its highest level since April 2023, with 58 per cent of manufacturers expecting their level of production to increase over the coming 12 months. This compared favourably to only 7 per cent anticipating a contraction. Improved sentiment reflected signs of stronger demand, new product launches, a better trading environment, export opportunities and hopes the cost and supply situations would move closer to normal conditions.

The tentative signs of growth and renewed optimism among manufacturers in March filtered through to other variables. Although levels of employment and purchasing activity continued to decline, rates of contraction eased noticeably. The pace of job loss was the slowest since last May, while input buying volumes fell to the weakest extent during the current 21-month sequence of decline.

Lower levels of purchasing along with delays in receiving goods ordered from suppliers, efforts to reduce safety stocks and cash flow management initiatives led to a further drop in stocks of purchases during March. Companies linked longer vendor lead times to the Red Sea crisis, as diversions of freight (especially from Asia) and the knock-on effect to downstream supply chains led to extended delivery times.

Holdings of finished products also declined in March. Lower inventories reflected cost-control programmes, lower safety stock requirements and settling existing contracts from stock. Backlogs of work subsequently fell for the twenty-third month in a row.

ALCHEMPro News Desk (DP)

Receive daily prices and market insights straight to your inbox. Subscribe to AlchemPro Weekly!